Nieuws

Onze ambitie

Onze ambitie is een significante bijdrage leveren aan het creëren van een volledig circulaire wereld.

Dit doen wij door afval en afvalwater te zuiveren van medicijnresten, virussen en bacteriën, zodat het schoon en herbruikbaar is. Door grondstoffen te herwinnen die tot voor kort als afval werden afgedaan. Door slimme toepassingen te bieden voor de omgang met risicovol afval. Kortom, door te focussen op die gebieden waar wij onze impact kunnen maximaliseren. Zoals ziekenhuizen en verzorgingstehuizen, of in nieuwe initiatieven zoals luierrecycling.

In nauwe samenwerking met technische partners en op basis van een open, modulair platform ontwikkelen wij circulaire oplossingen voor grote uitdagingen:

Dreiging antibioticaresistentie

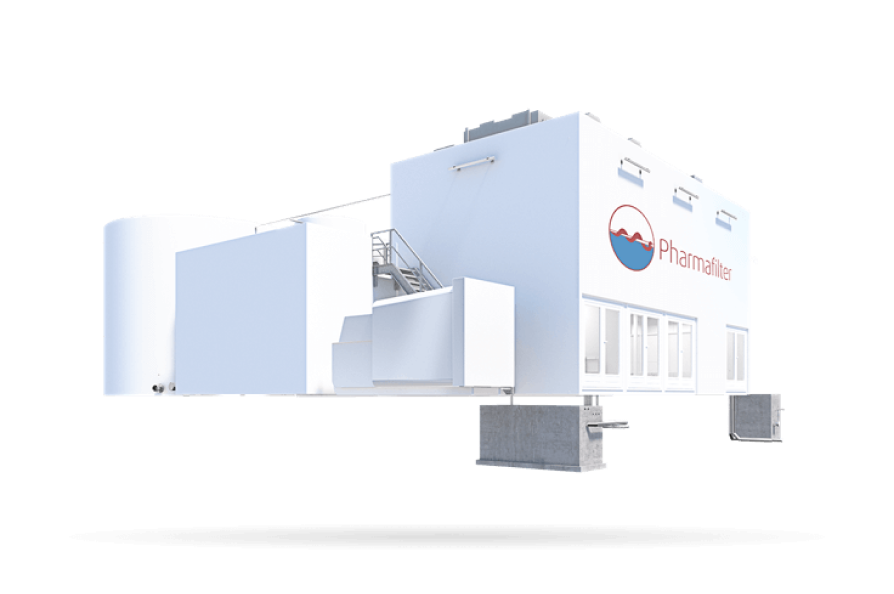

De WHO noemt medicijnresten, contrastvloeistoffen, hormoonverstoorders en multiresistente bacteriën in drinkwater bij de 10 grootste bedreigingen voor de gezondheid van de wereldbevolking. Met Pharmafilter geeft uw ziekenhuis water schoner terug aan de natuur dan voordat het gebruikt werd.

Lees meer

Hoge kosten biologisch gevaarlijk afval

Het transporteren en verwerken van biologisch gevaarlijk afval levert ziekenhuizen zowel logistieke uitdagingen als hoge kosten op. Het Pharmafilter-platform ontsmet ziekenhuisafval en maakt het als standaard grijs afval verwerkbaar voor circulaire toepassingen.

Lees meer

Veiligheid patiënten, medewerkers en bezoekers

Zorginfecties zorgen voor 5% van de totale jaarlijkse ziekenhuisopnamekosten. Omgang met besmettelijk ziekenhuisafval is een van de belangrijkste factoren van besmettingsrisico's van zorginfecties. Pharmafilter vermindert de hoeveelheid personeelsinteracties met ziekenhuisafval aanzienlijk en heeft zo directe, meetbare invloed op het aantal zorginfecties.

Lees meer

1

2

3

4

5

6

7

Vast afval

Het in de eerste stap van het proces gefilterde vaste afval krijgt eveneens een behandeling in de Pharmafilter-installatie. Afhankelijk van de samenstelling zal het afval vergist kunnen worden, waarbij biogas ontstaat voor de productie van duurzame elektriciteit en warmte. Het afval ondergaat in elk geval een proces van ontwatering en decontaminatie.

Hierna kan het afval veilig worden nagescheiden, ten behoeve van het hergebruiken van bijvoorbeeld plastics en edelmetalen in dit afval. Deze manier van afvalverwerking vergroot de circulaire mogelijkheden en verlaagt de CO2 footprint en de afvalinzamelings- en afvalverwerkingskosten voor het ziekenhuis.

Meer weten over wat Pharmafilter en de Tonto kunnen betekenen voor de duurzaamheidsdoelstellingen van uw ziekenhuis? Neem meteen contact op.